Strict classification ensures consistent diamond, full coverage and exposure of each diamond leading to efficient cutting and smooth preparation with reduced vibration.

Latest electroplating techniques ensure uniform diamond coating with strong bonding tech, making the burs resistant to wear and providing smooth cutting.

Imported natural diamond crushed and processed to remove impurities, demagnetized, rounded, and purified.

Controlled embedding depth ensures cutting efficiency, minimizes grit loss, and reduces heat accumulation, thus lowering the risk of pupal accidence.

One piece Precision Ground Shanks ensure the better concentricity and durability, with minimal heat generation with minimal heat generation, ensures maximum runout accuracy even after several uses and guarantees accurate work.

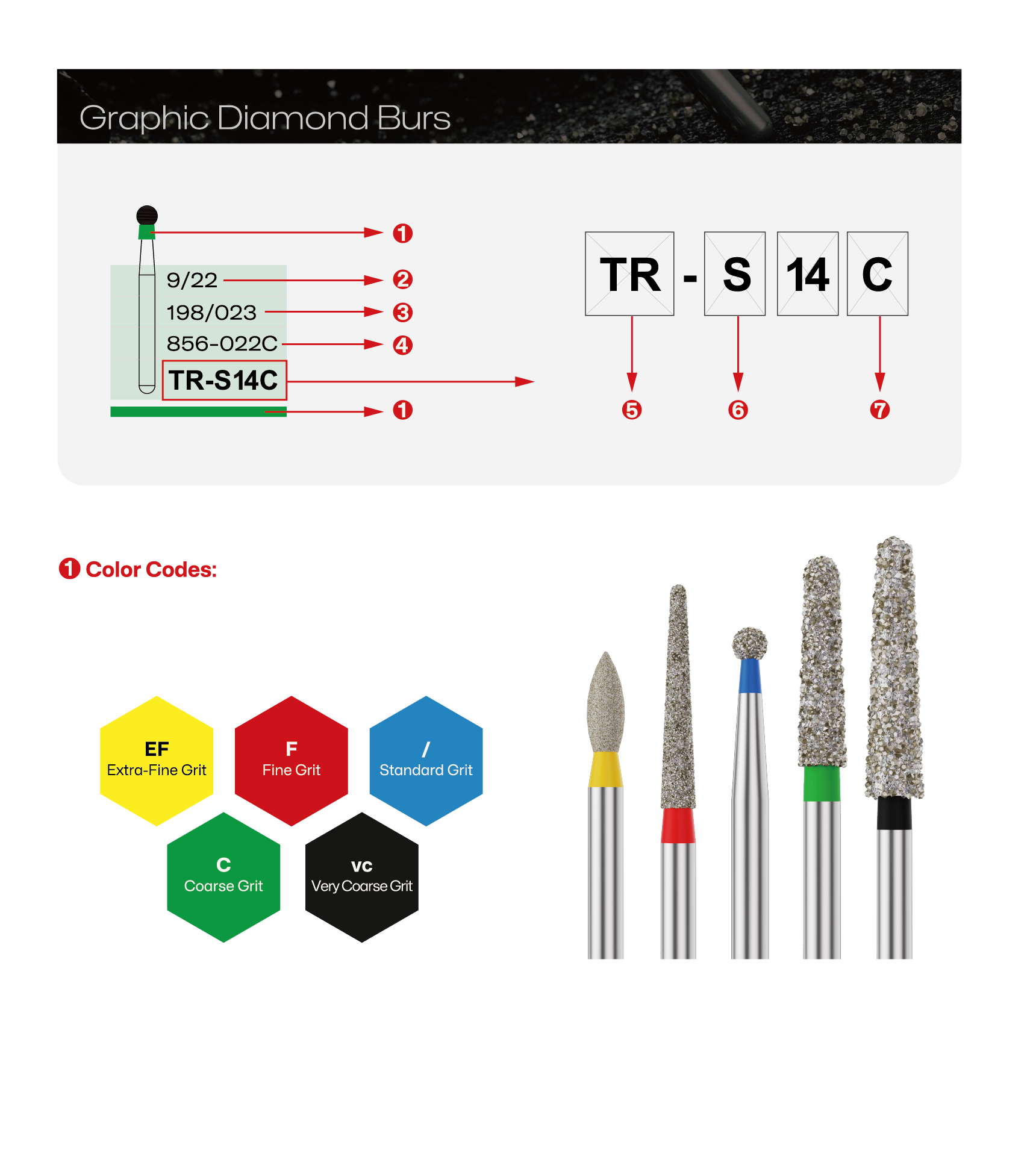

Color Codes

Yellow: EF( Extra-Fine Grit ), Red: F( Fine Grit ), Blue: Standard Grit,Green: C ( Coarse Grit ), Black: vc (Very Coarse Grit)

ISO No. ( Apical Diameter )

008~080

Shapes and Uses of Working Parts

BR ball, BC inverted cone, SI inverted cone, DI inverted cone, WR wheel, SF flat-end cylinder, TF flat-end taper, SR round-end cylinder, TR round-end taper, CR round-end taper, CF round-end taper, SO pointed cylinder, FO pointed flame, TC pointed taper, CD children's burs, EX special shapes, CE ceramic edge bur, RS round-edge cone

Shank Length Notations( standard shank unmarked)

S: Short shank, SS: Ultra-short shank, L: Long shank

Grit Size (standard grit unmarked)

EF: Extra-fine grit, F: Fine grit, C: Coarse grit, VC: Very coarse grit

Whether you are a beginner or an expert, this event will give you the opportunity to learn and progress

Product consultant one-on-one service

Free product solutions

Professional team meticulous answer